The DXR Flex 1025 and DXR Flex 1043 are Waygate Technologies’ first bendable detectors, representing a significant advancement in weld inspection technology. These detectors are specifically designed for in-field weld inspection, featuring battery operation, wired and wireless communication options, and compliance with both ISO 17636 and ASME V standards.

Key Features and Benefits

The DXR Flex detectors offer several advantages for weld inspection:

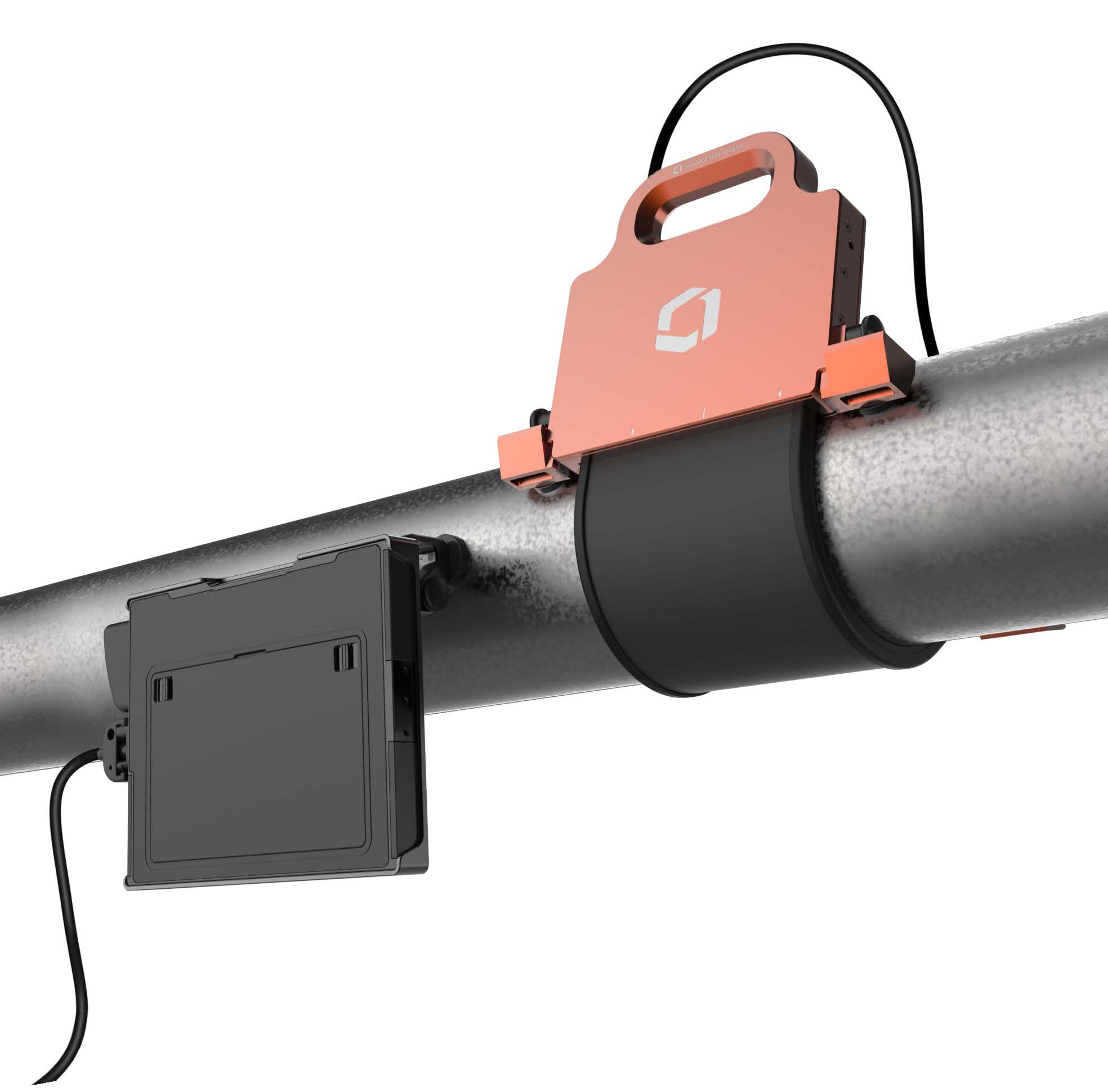

- Bendable Design: This unique feature enables double-sided exposures with consistent image quality, making it ideal for inspecting pipes, pressure vessels, and other curved surfaces.

- Two Sizes: The DXR Flex 1025 and 1043 are available in two sizes to accommodate different pipe diameters. The 1025 can be used on pipes with a minimum bending diameter of 6 inches, while the 1043 is suitable for pipes with a minimum bending diameter of 12 inches. For smaller diameters, a rigid side or DWDI (elliptical) technique can be employed for pipes below 4 inches.

- Easy Positioning: Integrated magnets and strapping mechanisms ensure easy and secure placement of the detector on the workpiece, even on non-magnetic materials.

- Rugged and Durable: The detectors are housed in a protective orange armor case that provides excellent protection against mechanical impact and ensures high visibility in the field.

- Wireless and Wired Communication: The DXR Flex detectors offer both wireless and wired communication options, providing flexibility and adaptability in various inspection environments.

- Battery Operated: With a battery life of 4 hours active and 6 hours standby, the detectors enable extended operation in the field without the need for external power sources.

- High Image Quality: The detectors utilize a dedicated scintillator that prioritizes resolution, resulting in exceptional image quality. Additionally, the ASTM-compliant calibration process, including Gain & Offset and Bad Pixel Map calibration, further enhances the image quality, exceeding industry standards.

Components and Operation

The DXR Flex detectors consist of two main components:

- Sensor Body: This component contains the scintillator responsible for capturing X-ray images. It is connected to the main body via a 3m cable.

- Main Body: The main body processes the pixel information from the sensor body and generates digital images. It communicates with the sensor body and the computer through wired or wireless connections. It also houses the battery and charging ports.

Software Integration

The DXR Flex detectors are fully integrated with the Rhythm Insight RT software, providing a comprehensive and user-friendly platform for image acquisition and analysis. This powerful software offers several key features:

- Intuitive Interface: The software features a touch user interface, making it easy to operate in various conditions.

- Automated Calibration: The software includes automated calibration procedures for the DXR Flex detectors, ensuring optimal image quality.

- Image Quality Validation Tools: Rhythm Insight RT provides a range of tools for validating image quality, ensuring compliance with industry standards.

- Compliance with Standards: The software adheres to various industry standards, including ASTM E2339 DICONDE, ASTM E2597/E2597M, ASTM E2698, ASTM E2737, ISO176363-2, GB/T 35388, and NB/T 47013.11.

Applications and Industries

The DXR Flex detectors are suitable for a wide range of weld-related applications, including:

- Pipeline Weld Inspection: The bendable design makes them ideal for inspecting welds on pipelines in the field and fabrication shops.

- Pressure Vessel Inspection: Their flexibility allows for efficient inspection of welds on pressure vessels and tanks.

- Crack Detection: The high image quality enables the detection of cracks and other defects in welds.

These detectors cater to various industries, including:

- Oil and Gas

- Nuclear

- Shipbuilding

- Power Generation

- Aerospace & Space

- Pulp & Paper

- Military & Defense

Conclusion

The DXR Flex 1025 and DXR Flex 1043 bendable detectors offer a game-changing solution for weld inspection. Their unique combination of flexibility, ease of use, and high image quality makes them ideal for a wide range of applications and industries. With their rugged design and comprehensive software integration, these detectors provide an efficient and reliable solution for ensuring weld integrity and enhancing safety in various industrial settings.