Table of Content

- Challenges in Automotive NDT Inspection

- NDT Solutions for the Automotive Sector

- Role of ‘NDTProducts’ in Providing Solutions

- Conclusion

- FAQs

The automotive industry relies heavily on NDT technology advancements to ensure vehicle safety, reliability, and quality, but faces numerous challenges in implementing effective methods. One of the main challenges is the need for continuous innovation and advancement in the automotive industry challenges face in NDT.

To keep up with evolving vehicle designs and materials. Additionally, there is a growing demand for more efficient and cost-effective NDT solutions to meet industry standards and regulations.

Challenges in Automotive NDT Inspection

The Automotive Industry NDT challenges are numerous, due to the need for faster inspection times, increased automation, and the demand for more advanced testing techniques to keep up with technological advancements in vehicle manufacturing.

A. Complex Geometries of Automotive Components

One of the primary challenges in Automotive NDT Inspection is dealing with the complex geometries of automotive components.

1. Difficulty in Inspecting Irregular Shapes

Automotive component inspection is often necessary because they have irregular shapes, making them difficult to inspect thoroughly. Traditional NDT methods with limited equipment may not effectively detect flaws in these components, leading to potential safety risks.

2. Limitations of Traditional NDT Methods

Conventional NDT Techniques, such as visual inspection, may not be sufficient for complex geometries. Advanced methods, such as ultrasonic testing and radiographic testing, are required to ensure automotive NDT standards compliance.

B. Material Diversity in Automotive Manufacturing

The automotive industry uses a variety of materials, each presenting unique challenges for NDT automotive component inspection.

1. Metals, composites, and plastics

Modern vehicles are constructed from a mix of metals, composites, and plastics. Each material has distinct properties that affect how they respond to NDT Methods.

2. Adapting NDT Techniques to Different Materials

NDT techniques must be adapted to suit the specific properties of each material. This requires specialised knowledge and equipment to ensure accurate inspection results.

C. High Production Rates

The automotive industry faces challenges in NDT manufacturing, which operates at high production rates, demanding rapid and efficient NDT processes.

1. Need for Speed Without Compromising Accuracy

Maintaining high-speed production while ensuring accurate NDT inspections is a significant challenge. Manufacturers need to strike a balance between speed and precision to meet production targets without compromising quality.

2. Automation in NDT Processes

Automation is key to achieving this balance. Automated NDT systems can perform inspections quickly and consistently, reducing the risk of human error and increasing efficiency.

D. Stringent Safety and Quality Standards

Automotive manufacturers must adhere to stringent safety and quality standards, making thorough NDT essential.

1.Regulatory Requirements

Regulations mandate rigorous inspection protocols to ensure vehicle safety. Meeting these requirements is a constant challenge for manufacturers.

2. Meeting Customer Expectations

Customers expect high-quality, reliable vehicles for use, this requires quality control in automotive manufacturing. Manufacturers must implement effective NDT processes to meet these expectations and maintain their reputation.

NDT Solutions for the Automotive Sector

Several advanced NDT technologies address the challenges faced by the automotive industry.

1. Ultrasonic Testing:

Ultrasonic testing uses high-frequency sound waves to detect internal flaws in materials. It is particularly effective for inspecting metals and composites used in automotive manufacturing.

The KrautkrÄmer USM GO+ is a compact yet powerful NDT device designed for field inspection, offering light, intuitive controls, and reliable defect detection.

The DMS Go+ Series Ultrasonic Thickness Gauge is a portable and powerful handheld tool suitable for various applications and environments for measuring and managing thickness.

2. Radiographic Testing:

Radiographic testing employs X-rays or gamma rays to create images of a component’s internal structure. This method is useful for detecting defects in complex geometries. Waygate Technologies offers phosphor imaging plates for CRxFlex II, enhancing image quality, exposure speed, and lifespan, combining high dose-sensitivity with a wide dynamic range for industrial use.

3. Magnetic Particle Testing:

Magnetic particle testing involves applying a magnetic field to a component and using magnetic particles to detect surface and near-surface defects. It is commonly used for inspecting ferromagnetic materials.

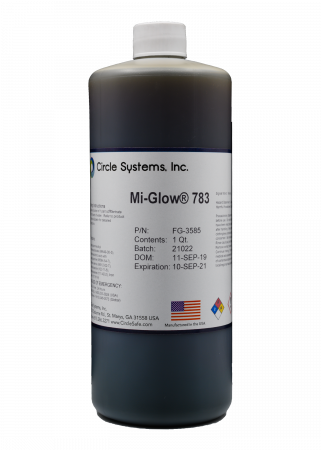

NDT Products represents Circle Systems, Inc. magnetic particle inspection products in Canada, utilising advanced chemical technologies and manufacturing methods for over 40 years.

Role of NDT Products in Providing Solutions

NDT Products offers a range of solutions to address the challenges in automotive NDT.

1. Good Product Range

NDT Products provides a Wide Range of Equipment and solutions for various NDT methods.

2. Equipment for All Major NDT Method

Their product range includes equipment for ultrasonic testing, radiographic testing, magnetic particle testing, and more. This selection ensures that manufacturers have access to the right tools for their specific needs.

NDT Products offers REL, Inc. UV lighting, radiometers, and accessories for the automotive industry.

3. Custom Solutions for Specific Needs

NDT Products also offers custom solutions tailored to the unique requirements of automotive manufacturers. This customisation ensures optimal performance and accuracy in NDT processes.

Conclusion

Improving NDT efficiency in the automotive industry faces numerous challenges in implementing effective NDT processes. However, advanced technologies and solutions provided by NDT Products help address these challenges.

By leveraging innovative equipment, expertise, and support services, automotive manufacturers can ensure the safety, reliability, and quality of their vehicles. Continued innovation in NDT is essential for meeting the evolving needs of the automotive industry.

FAQS

1. What solutions does NDT Products offer for the integration of new materials and technologies in the automotive industry?

A: NDT Products offers advanced ultrasonic, eddy current testing, and many other tools that can effectively evaluate materials.

2. How do NDT Products help the automotive industry achieve cost-efficiency in NDT?

A: NDTProducts provides durable, reliable, and easy-to-use NDT equipment that reduces the need for frequent replacements and maintenance.

3. In what ways does NDT Products ensure rapid and high-quality inspections for automotive manufacturers?

A: NDT Products ensures rapid and high-quality inspections by offering advanced NDT tools that provide quick and precise results. Their products are designed for easy integration into production lines, allowing for seamless and continuous inspections without slowing down the manufacturing process.