Description

DXR Flex 1025 & 1043

Designed specifically for industrial applications, the next generation of DXR detectors delivers rugged reliability tailored to meet the demanding requirements of weldment inspection. Engineered with customer needs in mind, the DXR Flex Detector excels in three standout features: exceptional flexibility, user-friendly operation, and rapid performance. This combination ensures a versatile and efficient solution for diverse inspection tasks.

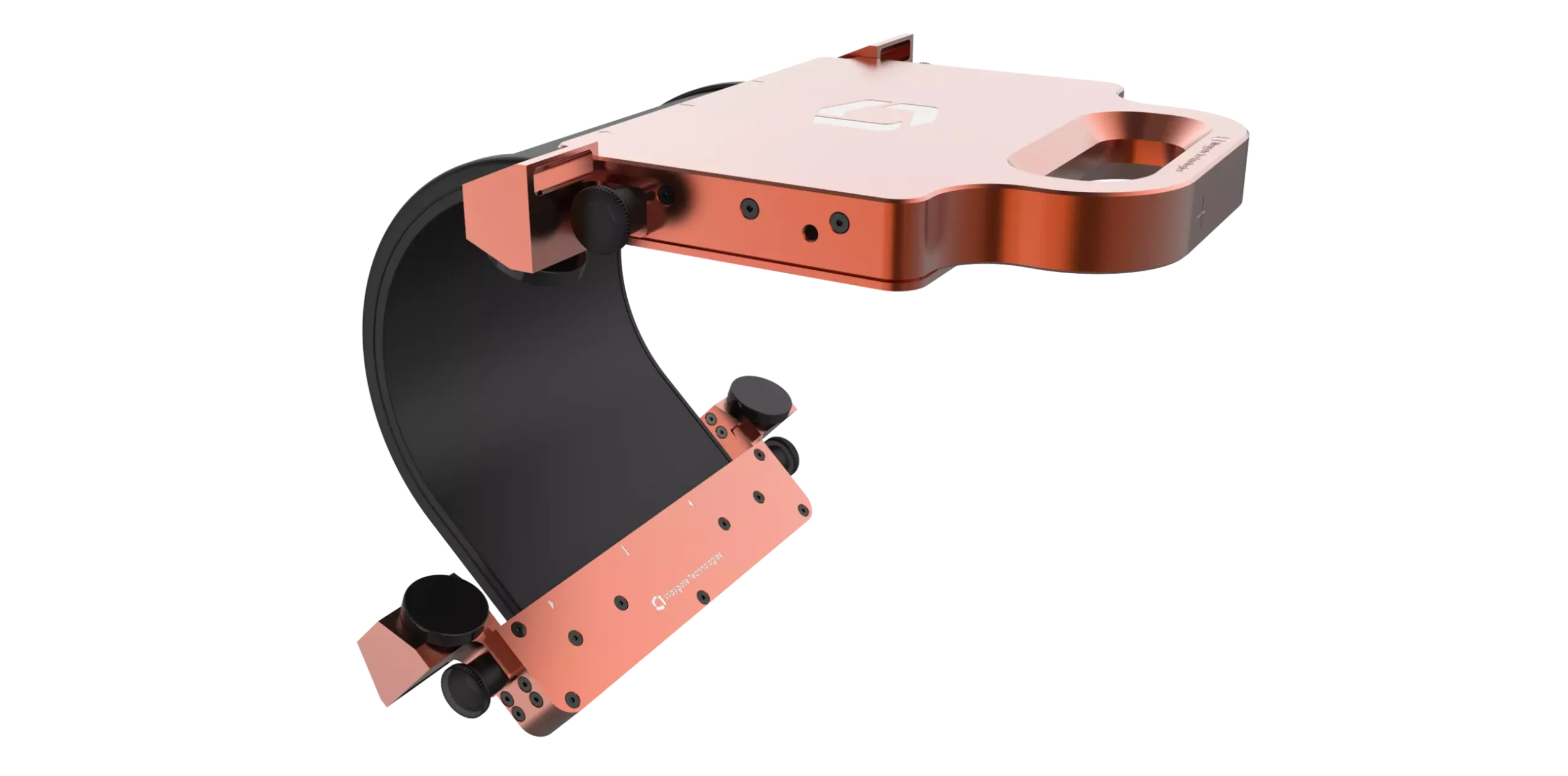

A standout feature of the DXR Flex Detector is its dual-sided exposure capability. One side of the detector is flexible, while the other is rigid, catering to elliptical radiographic exposures. This dual functionality ensures comprehensive and precise inspections, meeting diverse application needs.

Our first bendable detectors

Dedicated to industrial use, this customer driven design of the next generation of DXR Detectors offers a rugged reliability that perfectly matches the criteria for the inspection of a wide range of

weldments.

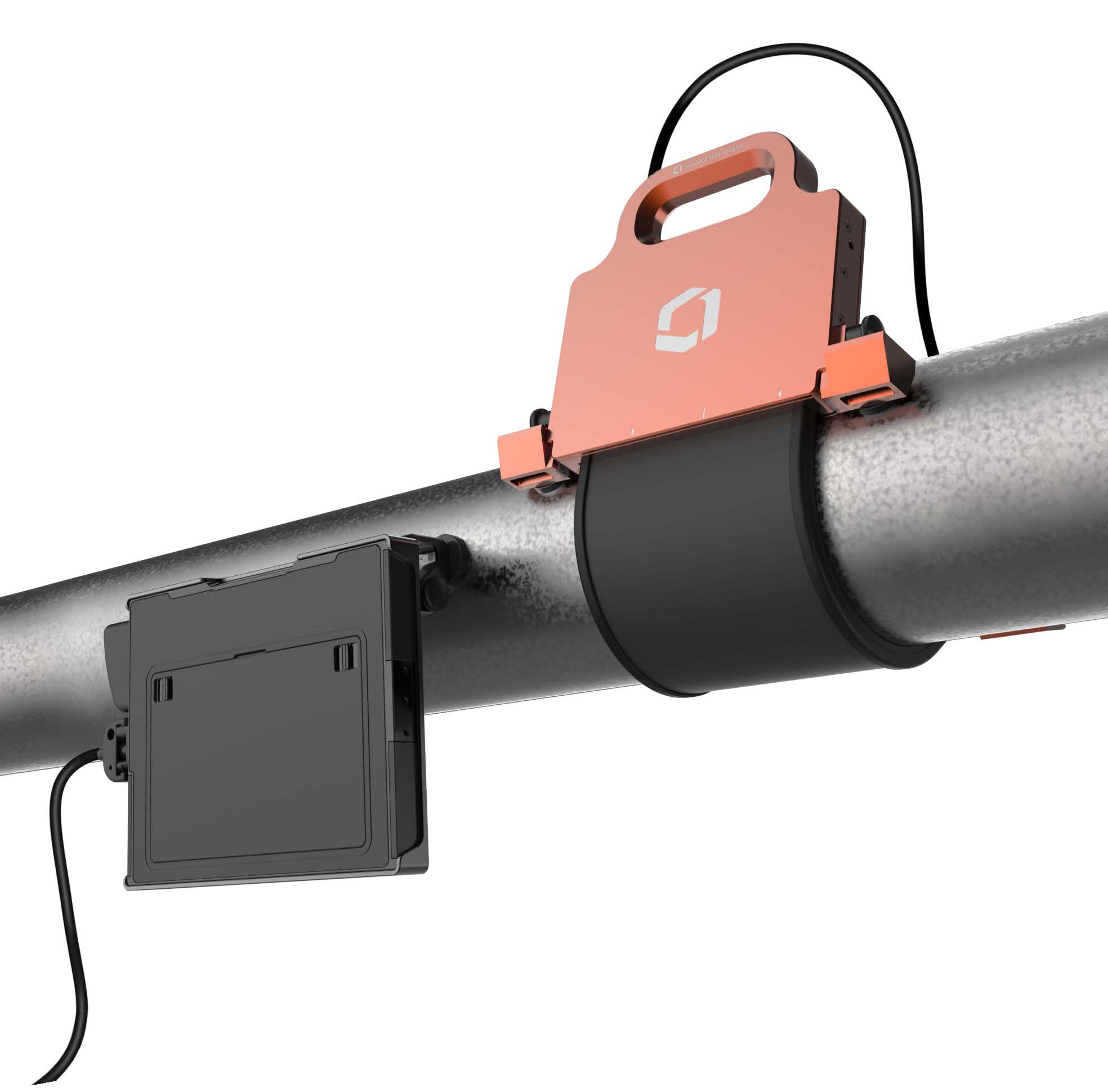

Flexible: The new DXR Flex Detectors are designed to allow exposures from both sides of the detector: one side is flexible and therefore suitable for tubular contact radiography (DWSI) where the other side is rigid, supporting non-contact radiographic exposure techniques as well.

Easy: Each detector comes in a ruggedized casing with magnets for fast and easy weld access and industrialized shielding to protect against drops, knocks, and indirect radiation for extended life.

Fast: DXR Flex Detectors are battery operated and can be used in either wired or wireless communication mode to help simplify each inspection while driving productivity and adapting to any environment and/or location.

|

The new DXR Flex is a perfect fit for a wide range of weld related applications

|

and in a variety of market segments

|

Compliant to following NDT standards for weld inspection:

|

*basically any weld application that currently utilizes conventional film*

Fully integrated in Rhythm Insight software Built on 15 years of experience and proven knowledge, Rhythm Insight RT offers a powerful, scalable, yet easy-to-use NDT acquisition and analysis platform, dedicated to industrial requirements, and powered by Flash!

- Intuitive user interface, right out of the box

- Touch user interface for optimal operation under all conditions

- Application-guided automation

- Powerful image quality validation tools

- ASTM E2339 DICONDE compliant

- Compliant with prevailing standards, including ASTM E2597/E2597M, ASTM E2698, ASTM E2737, ISO176363-2, GB/T 35388, NB/T 47013.11 etc.

- Powered by Flash! automatic image processing

technology - Always updated, never out of date

Browse our other Digital X-Ray products from Waygate Technologies here