Description

For more than 30 years, Waygate Technologies has been recognized internationally for our high-quality eddy current instruments and accessories. Carrying the legacy of Hocking NDT, our products are among the world’s most advanced for the detection of cracks and flaws, both during and after production processes. Wherever metals are used, you can turn to the specialist knowledge of Waygate Technologies for our cost-effective, innovative design and manufacturing solutions

Why eddy current?

Eddy current is a fast, accurate and cost-effective electro-magnetic non-destructive testing method for the detection of surface or nearsurface flaws as well as heat treatment verification. Its uses range from the inspection of raw materials to quality control of finished products to maintenance inspections. Additional advantages of eddy current inspections include:

- Highly accurate and repeatable flaw detection

- High inspection speeds with low surface preparation

- Flaw detection through coatings, such as paint

- Good discrimination between flaw types with no couplant, consumables or radiation hazards

Why Waygate Technologies?

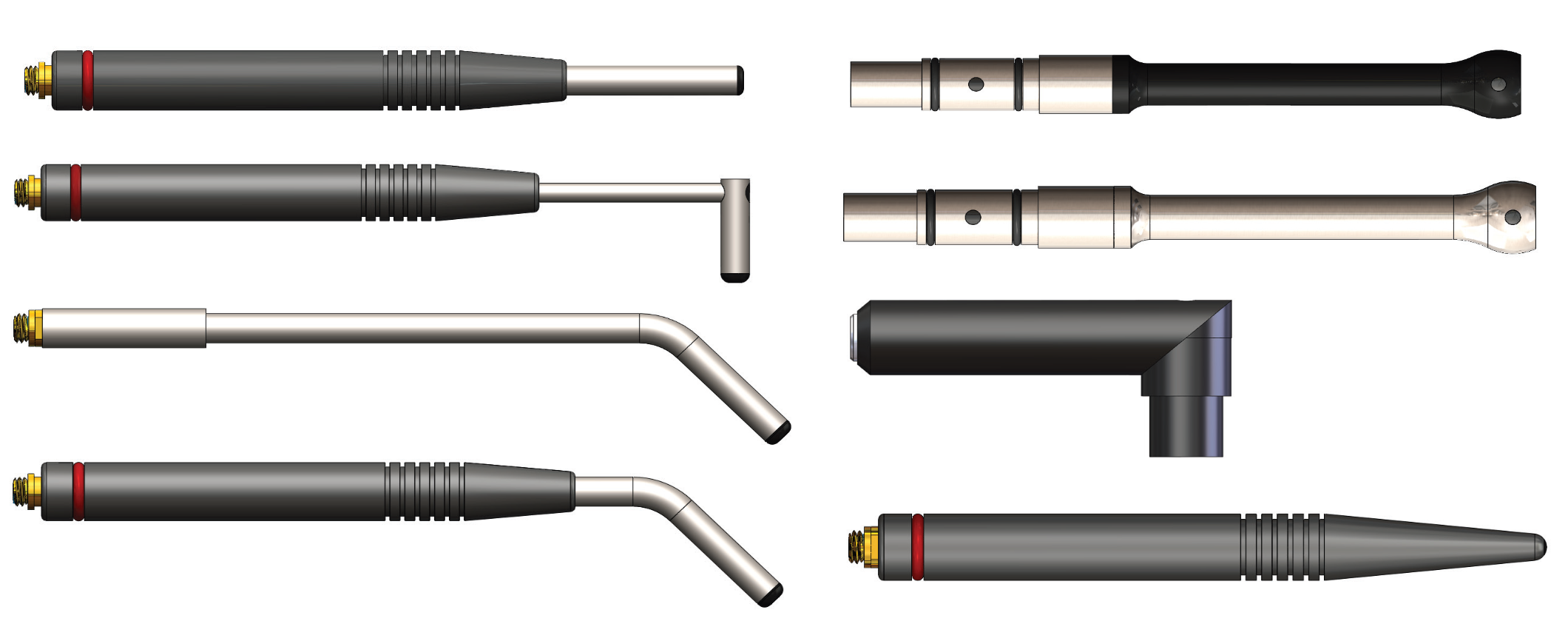

We provide full eddy current solutions, from hand-held devices to probes for standard and special applications. Designed to meet industry’s most stringent standards, our solutions are registered to the highest international quality standard ISO9001.