Table of Content

- Errors During Film Exposure

- Errors During Film Handling

- Storage and Processing Errors

- Preventative Measures

- Conclusion

Radiography is an essential tool for providing critical insights into various devices and machines. However, the process of capturing these images isn’t fool proof. Various errors can occur during film exposure and handling, potentially compromising quality and machine safety. Understanding these errors in film exposure or handling how to prevent them is vital for any radiographic technician.

Errors During Film Exposure

One common error during film radiography NDT exposure is improper positioning, resulting in distorted images. Additionally, over or underexposure to the film can lead to poor image quality and difficulties in interpretation.

A. Incorrect Exposure Time

1. Overexposure

Overexposure happens when the film is exposed to too much radiation, resulting in images that are too dark. These overexposed film issues can obscure important details, making it difficult to diagnose conditions accurately.

2. Underexposure

Conversely, underexposed film problems occur when the film receives insufficient radiation. This leads to images that are too light, lacking the necessary contrast to discern structures clearly.

B. Improper Positioning of the Patient

1. Misalignment

Misalignment is a common film processing error where the device or object is not properly positioned, causing the parts to be cut off or misrepresented in the radiograph.

2. Motion Artifacts

The movement of the object during exposure can create blurry images. Ensuring that the object or machine is not disturbed is important for capturing clear and quality images.

C. Inaccurate Beam Alignment

1. Off-Centering

If the X-ray beam is not centred correctly over the area of interest, it can result in missing critical parts of the device, leading to incomplete or misleading images.

2. Angulation Errors

Incorrect film storage angulation by the X-ray beam can distort the structures, making it difficult to interpret the images accurately.

Errors During Film Handling

Errors during radiography film exposure or handling can include light leaks in films, improper storage leading to fogging, and physical damage such as scratches or creases. It is important for radiographers to be vigilant in their handling of films to ensure accurate and clear imaging results.

A. Handling Artifacts

1. Fingerprints

Fingerprints on the film can create unwanted marks that obscure essential information. Wearing gloves and handling films by the edges can prevent this.

2. Scratches

Scratches can occur if films are handled roughly or with sharp objects. These scratches can mimic or obscure important details.

B. Light Leaks

1. Darkroom Errors

Light leaks in the darkroom can cause film fogging issues, reducing image clarity. To avoid this, ensure that the darkroom is completely sealed.

2. Cassette Problems

If the cassette that holds the film is not properly sealed, light can enter and expose the film prematurely, ruining the image.

C. Chemical Contamination

1. Developer and Fixer Contamination

Film contamination by developing chemicals can lead to uneven development, creating areas of varying density on the film.

2. Water Spots

Film handling mistakes such as washing or drying can leave water spots on the film, which can interfere with image quality.

Storage and Processing Errors

Storage errors can lead to film fogging or damage, such as film exposure problems to light or heat. Processing errors can result in uneven development, chemical contamination, or improper fixing, affecting the quality of the radiographic images. These kinds of radiographic film handling issues can have a very bad impact.

A. Improper Film Storage

1. Temperature Control

Storing films at inappropriate temperatures can degrade their quality over time. It’s crucial to store films in a cool, dry place.

2. Humidity Issues

High humidity can cause films to stick together or become distorted, leading to poor image quality.

B. Errors in Film Processing

1. Incorrect Developing Time

Developing the film for too long or not long enough can result in images that are either too dark or too light, respectively.

2. Inconsistent Agitation

Proper agitation during development ensures even chemical distribution. Inconsistent agitation can lead to uneven development and poor-quality images.

C. Impact of Errors on Diagnostic Quality

1. Reduced Image Quality

Errors in film exposure or handling can significantly reduce image quality, making it difficult for radiologists to interpret the images accurately.

2. Diagnostic Ambiguity

Poor-quality images can lead to diagnostic ambiguity, potentially resulting in misdiagnoses or delayed treatment.

C. Increased Need for Re-exposure

1. Patient Safety Concerns

Errors in film exposure or handling often necessitate retaking the images, exposing patients to additional radiation, which poses safety concerns, particularly for vulnerable populations.

D. Economic Implications

1. Increased Costs

Repeated exposures and the need for additional materials increase costs for industry facilities, impacting overall efficiency and resource allocation.

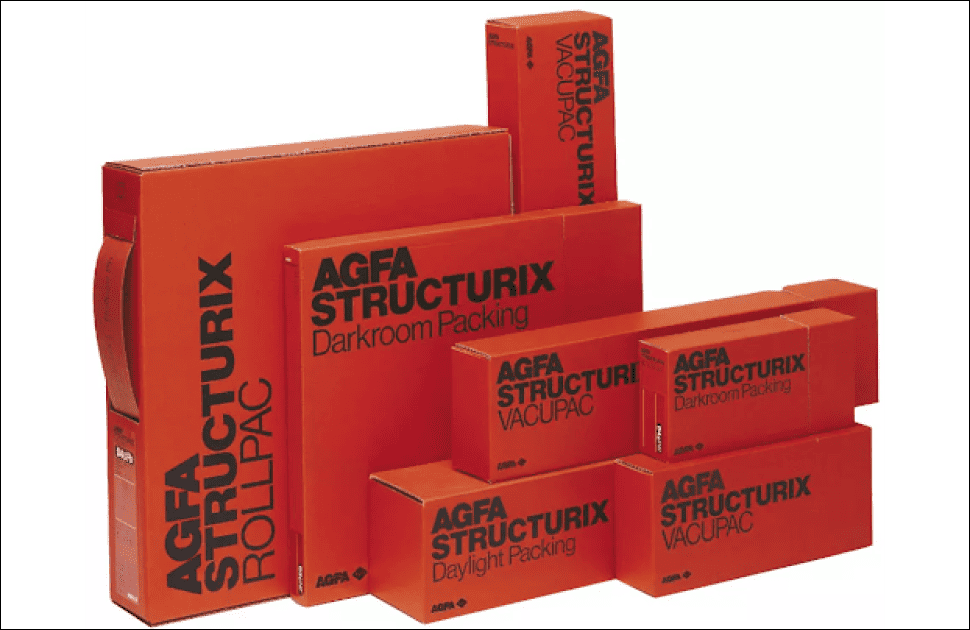

Waygate Technologies created the high-quality, durable radiographic film known as Agfa Structurix NDT X-Ray Film. It offers a range of films, from ultrafine grain to high speed, in various sheet sizes and packaging options.

Waygate Technologies offers a range of Agfa Structurix X-Ray Film Processors, ranging from tabletop models to sophisticated models, designed for high-quality results. These processors are suitable for various applications and can be processed manually or automatically.

Waygate Technologies CRxFlex II CR Scanner is a versatile, multipurpose, and efficient NDT scanner designed for asset inspections. It offers superior performance, throughput, and image quality, with lower radiation dose requirements for isotope and X-ray imaging.

Preventative Measures

Errors in film exposure or handling during radiography, such as light leaks, improper storage, and physical damage to the film, can occur. To prevent radiographic film processing errors, it is important to store the film in a cool, dry place away from direct sunlight and to handle it carefully to avoid bending or tearing. Additionally, regularly checking equipment for any malfunctions can help ensure accurate results.

A. Proper Training

1. Continuous Education

Continuous Education and Training for radiographic technicians can help reduce the occurrence of errors by keeping them informed of best practices and new technologies.

2. Competency Assessments

Regular assessments ensure that technicians maintain a high level of competency and can perform their duties effectively.

B. Quality Control Procedures

1. Routine Equipment Checks

Routine Checks and Maintenance of Radiographic Equipment help prevent malfunctions that can lead to exposure errors.

2. Regular Maintenance

Regular maintenance of darkrooms, cassettes, and processing equipment ensures they are in optimal condition, reducing the risk of handling errors.

C. Safe Handling Practices

1. Standard Operating Procedures

Implementing and following standard operating procedures for film handling can minimise the risk of handling artefacts.

2. Ergonomic Practices

Ergonomic practices in handling films and positioning patients can help prevent errors in film exposure or handling and improve overall workflow efficiency.

Conclusion

Radiography is a crucial, but errors in film exposure or handling can compromise its effectiveness. By understanding these errors and implementing preventative measures, radiographic technicians can ensure high-quality images. With a commitment to innovation and customer satisfaction, NDT Products stands at the forefront of the NDT industry, offering not just products, but the best solutions tailored to meet the unique requirements of each client.